Brussels, 21st January 2022. EucoLight, the European Association of collection and recycling organisations for Waste Electrical and Electronic Equipment (WEEE) lamps and lighting, has successfully carried out a study with Fraunhofer IZM on the technical feasibility of the automatic identification of lamp types in the lamp waste stream.

The study focused on the separation of collected End-of-Life lamps, to separate conventional gas discharge lamps (GDLs) from light-emitting diode (LED) lamps.

The project commenced with a theoretical phase in which technological options for sorting methods were explored and described. Based on this analysis, a testing phase followed, concentrating on static and dynamic testing with three promising sorting technologies.

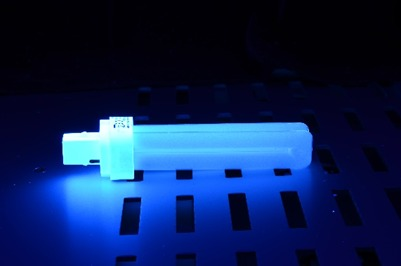

Ultimately two methods, using blue light and electromagnetic induction were considered promising and taken forward. The test results showed that electromagnetic induction successfully detected 100% of non-broken GDLs. Broken GDLs are not detected using this approach, since the gas needed to respond to the field has been lost.

The electromagnetic field tests have also shown that the large chip area of LED filament lamps can light up due to induction, but these can be excluded by employing suitable optical filters.

The blue light results showed that 60-90% of LED lamps were correctly detected. This recognition rate may be increased by aligning the lamps so that they can be lit directly in combination with more sensitive optical sensors. This will require further testing. Since a few GDLs also showed a reaction to blue light, these exceptions would have to be removed manually or via image recognition.

A combination of both methods, perhaps by integration within one optical detection lens, could present a promising approach for a practical application to enhance lamp recycling.

In particular, Fraunhofer IZM investigated the success rate of the electromagnetic approach and also recommends combining it with optical detection. Using samples from one of the German lamp treatment plants, it was successfully demonstrated that the combination of sensitive optical sensor, electromagnetic induction and selection via blue light improves the sorting and recycling process not only in terms of quality but also in terms of process speed.

The full study can be found at www.eucolight.org. Based on this study EucoLight hopes to initiate the development of recycling processes to make them more efficient and to gain higher level of material recovery.

About EucoLight

EucoLight is The European association of collection and recycling organisations for WEEE lamps and lighting. On behalf of its members, EucoLight engages with everything related to the WEEE Directive, legislations and standards affecting the collection and recycling of WEEE lighting. Its members collect and recycle, in aggregate, 80% of the lamp waste collected in the 18 countries in which they operate. EucoLight is the voice of European WEEE compliance schemes specialised in managing the collection and recycling of WEEE lighting; working to make the circular economy a reality for lighting products. EucoLight has 19 PRO members: AMBILAMP (Spain); Appliances Recycling SA (Greece); Ecolamp (Italy); Ecosystem (France); Ekogaisma (Estonia); Ekolamp s.r.o. (Czech Republic); Ekolamp Slovakia; Electrão (Portugal); Electro-Coord (Hungary); ElektroEko (Poland); FLIP (Finland); Lightcycle (Germany); LightRec (Netherlands); LWF (Denmark); Recolamp (Romania); Recolight (UK); Recupel (Belgium); UFH (Austria) and one affiliate member, LightingEurope. Founded mid-2015, EucoLight has quickly embarked into constructive dialogue with relevant stakeholders to provide expertise in the field of management and treatment of WEEE lighting and to promote the positive role of Extended Producer Responsibility schemes on the environment and society.

For more information, visit the EucoLight website www.eucolight.org, follow EucoLight on Twitter (@EucoLight) or contact the Secretary General, Marc Guiraud (marc.guiraud@eucolight.org).

About Fraunhofer IZM

Fraunhofer IZM specializes in industry-oriented applied research. The institute develops assembly and interconnection technology, also known as electronic packaging. Almost invisible and undervalued by many, electronic packaging is at the heart of every electronic application. These technologies connect the individual components, protect components and devices from vibration and moisture, and reliably dissipate heat. Fraunhofer IZM thus ensures that electronic devices continue to function reliably in even the harshest conditions. Modern packaging technologies make developing smaller and smaller products possible. They process ICs thinner than a sheet of paper. The institute, founded in 1993, has a staff of more than 400 and disposes of a lab area of over 8,000 sqm. About 80 percent of the turnover in 2021 was earned through contract research.

* Digitalizing the recycling stream of lamps: Using blue light and electromagnetic induction, lamp waste can be detected with up to 100% accuracy. The investigations were carried out in cooperation with OUT e.V.

©Fraunhofer IZM

– ENDS –